Fretting string

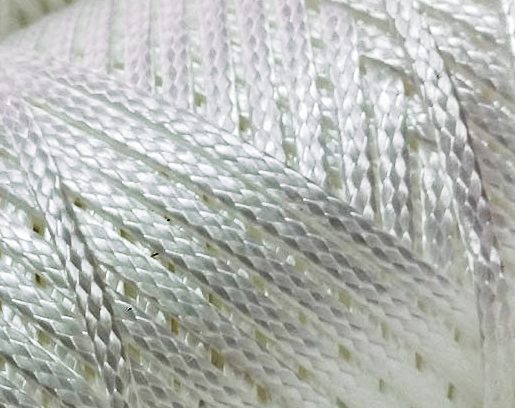

Braided

Easy to assemble and secure

all types of wiring

A practical solution for securing and organizing cables, wires and electronic components

Technical specifications

Composition

Depending on the use and the standard required, these strings are braided with the following materials:

- Meta-Aramid (use between -55°C and +240°C in continuous application, with possible peaks of use at +360°C)

- Teflon / PTFE mutlifilament (use between -73°C and +232°C)

- Fiberglass (use between -55°C and +430°C)

- Polyamide 6.6 (use between -55°C and +120°C)

several types of impregnation are available: microcrystalline wax (fungicide), PTFE or polyethylene (better abrasion resistance), elastomer or silicone coating (better knot retention)...

Application Standards

Depending on the product and the treatment chosen:

AIRBUS NSA8420-1

AIRBUS NSA8420-2

AIRBUS NSA8420-3

AIRBUS NSA8420-4

AIRBUS NSA8420-5

AIRBUS NSA8420-6

AIRBUS NSA8420-7

AIRBUS NSA8420-8

MIL-A-A-52080

MIL-A-A-52081

MIL-A-A-52082

MIL-A-A-52083

MIL-A-A-52084

Available diameters / widths

From 1.0 mm to 5.6 mm depending on product

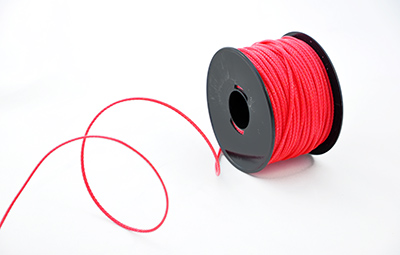

Packaging

Rolls or coils according to the standard

Discover

Our other models